Robotic

Teacher, Instructor, E-Mentor, R&D and Consulting

——

#DonLucElectronics #DonLuc #Teacher #Instructor #EMentor #RD #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

Teacher, Instructor, E-Mentor, R&D and Consulting

- Programming Language

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi, Arm, Silicon Labs, Espressif, Etc…)

- IoT

- Wireless (Radio Frequency, Bluetooth, WiFi, Etc…)

- Robotics

- Automation

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Machine Learning

- Artificial Intelligence (AI)

- RTOS

- eHealth Sensors, Biosensor, and Biometric

- Research & Development (R & D)

- Consulting

I am a highly skilled programming language, microcontrollers, IoT, robotics and etc; with over 45 years of experience in various industries. I graduated from McGill University, Montréal, Québec, Canada with B.Sc. and D.D.S. degrees. I started consulting with small and medium-sized businesses in my native Canada in the mid-eighties and by the mid-nineties I was consulting for large corporate clients like Fannie Mae, KPMG Peat Marwick, Chase Manhattan Foreign Trade Division (Hong Kong), Warner Lambert and a variety of other firms in the Washington, DC and New York City area. Later on I worked with clients in Europe, Mexico, and Latin America.

I have worked, lived and traveled all over the world and I am a trilingual (English, French, and Spanish).

Over the years I have been the CTO of various early stage IT startups, the owner of an IT consulting company (desktop, web, mobile, microcontroller and embedded systems) with clients worldwide, in charge of R&D projects to integrate hardware and software solutions in innovative ways, director of technology for a business software development company, designer and integrator of electronic hardware and head developer on a variety of software and technology projects.

I have seen many trends come and go, good and bad, and lived through many major industry changes. I do deplore some of the current state of the industry, and applaud some of the new trends. My wife had been telling me for years to write about the the industry as we discuss things a lot and she always tells me that I was born to teach, or preach when I get excited about a subject. Since my motto has always been to learn something new daily, and that a wasted day is one where you learn nothing new, I decided to share some of that hard-earned let’s call it “Wisdom” for lack of a better term.

I know that I am considered as a dinosaur in this business where you are considered old when you hit 25, but there are some of us old fogies at over twice that, that are still active and can still provide a full contribution to this or these fields. Besides consulting and custom programming, I also offer electronic hardware integration and design, hardware/software integration as well as R&D services. I provide my services worldwide and can work from my office or yours depending on your project’s needs.

Schedule of Services Teacher, Instructor and E-Mentor

- Beginner: These beginner-friendly microcontrollers are easy to use and program with just a computer or laptop, a USB cable, and some open-source software.

- Intermediate: Internet of Things (IoT).

- Advanced: Robotics, engineering, fashion, medical, environmental, performing arts, etc…

- Projects: TBD

- Research & Development: TBD

- Consulting: TBD

Luc Paquin – 2024

The Electronic, Programming Language, Microcontrollers, IoT, Robotics Experts.

Curriculum Vitae 2024

https://www.donluc.com/luc/LucPaquinCVEng2024Mk01.pdf

Luc Paquin – Programming Language 2024

https://www.donluc.com/luc/LucPaquinProgrammingLanguage2024Mk01.pdf

People can contact us: https://www.donluc.com/?page_id=1927

Follow Us

Luc Paquin – Curriculum Vitae – 2023

https://www.donluc.com/luc/

Web: https://www.donluc.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/@thesass2063

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

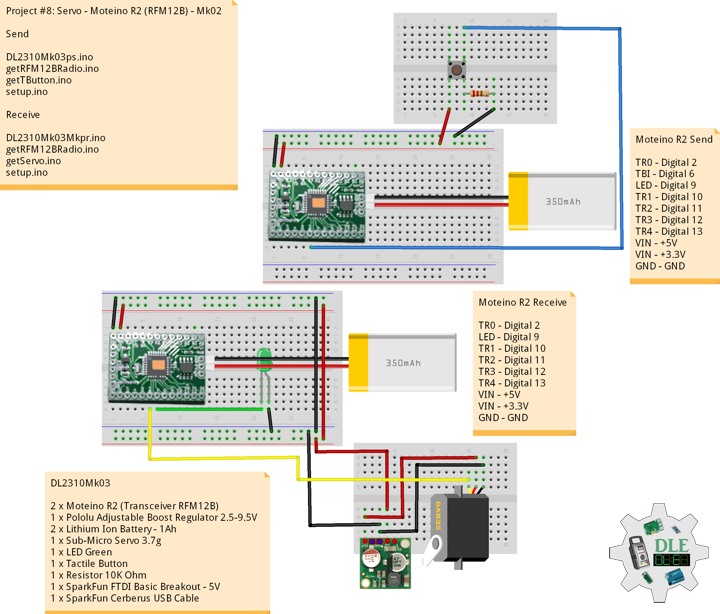

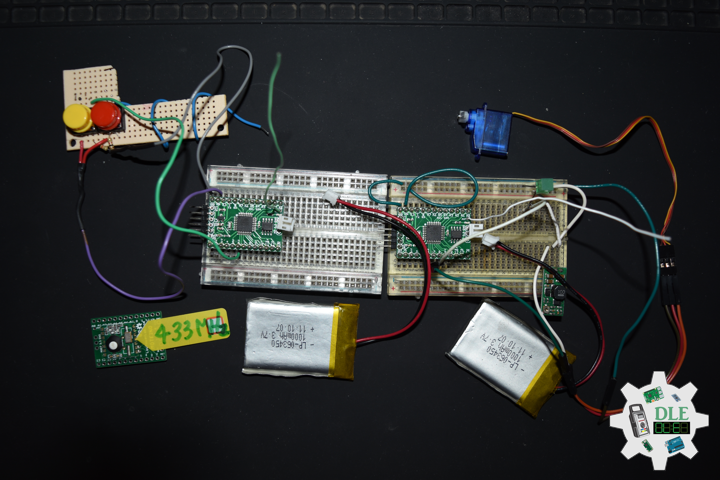

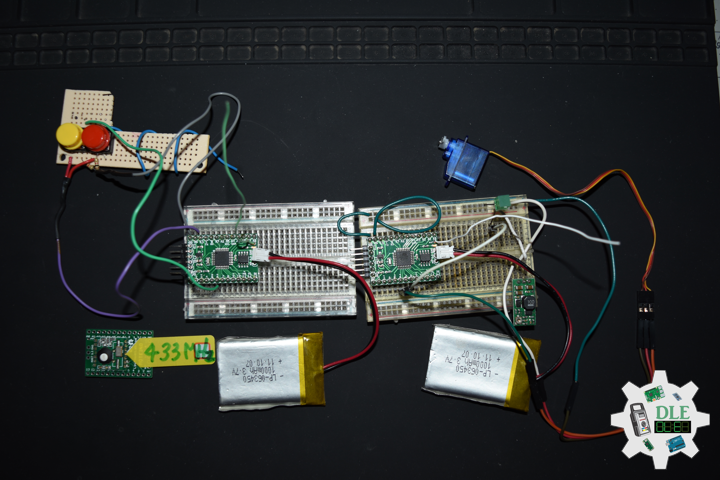

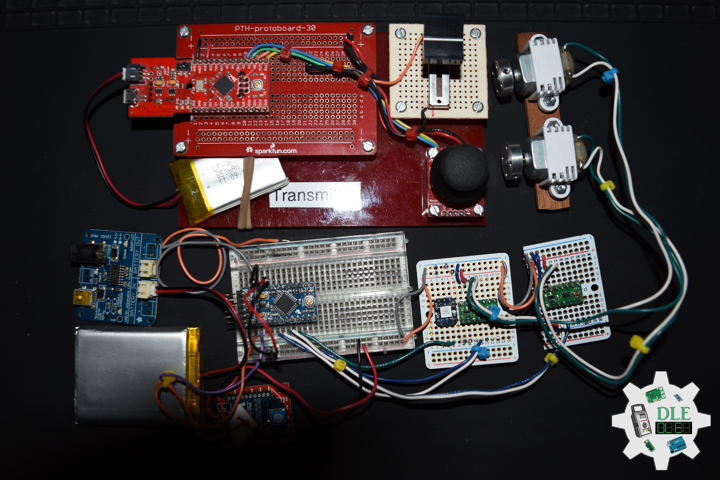

Project #8: Servo – Moteino R2 (RFM12B) – Mk02

——

#DonLucElectronics #DonLuc #Servo #Moteino #Transceiver #RadioFrequency #Pololu #Arduino #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——

Moteino

Moteino began as a low power wireless Arduino compatible development platform based on the popular ATmega328p chip used in the Arduino UNO. There are now several Moteino development boards including MoteinoMEGA based on the Atmega1284P and MoteinoM0 based on the SAMD21G18 Cortex M0+. For programming you will need an external FTDI-Adapter to load sketches, the advantages being lower cost, smaller size.

Servo Motor

A servo motor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servo motors.

Servo motors have been around for a long time and are utilized in many applications. They are small in size but pack a big punch and are very energy-efficient. These features allow them to be used to operate remote-controlled or radio-controlled toy cars, robots and airplanes. Servo motors are also used in industrial applications, robotics, in-line manufacturing, pharmaceutics and food services.

Pololu Adjustable Boost Regulator 2.5-9.5 Volt

This powerful, adjustable boost regulator can generate an output voltage as high as 9.5 Volt from an input voltage as low as 1.5 Volt, all in a compact. A trimmer potentiometer lets you set the boost regulator’s output voltage to a value between 2.5 and 9.5 Volt.

DL2310Mk03

2 x Moteino R2 (Transceiver RFM12B)

1 x Pololu Adjustable Boost Regulator 2.5-9.5V

2 x Lithium Ion Battery – 1Ah

1 x Sub-Micro Servo 3.7g

1 x LED Green

1 x Tactile Button

1 x Resistor 10K Ohm

1 x SparkFun FTDI Basic Breakout – 5V

1 x SparkFun Cerberus USB Cable

Moteino R2 (Send)

TR0 – Digital 2

TBI – Digital 6

LED – Digital 9

TR1 – Digital 10

TR2 – Digital 11

TR3 – Digital 12

TR4 – Digital 13

VIN – +5V

VIN – +3.3V

GND – GND

——

DL2310Mk03ps.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #8: Servo - Radio Frequency - Mk02

6-02

Send

DL2310Mk03ps.ino

2 x Moteino R2 (Transceiver RFM12B)

1 x Pololu Adjustable Boost Regulator 2.5-9.5V

2 x Lithium Ion Battery - 1Ah

1 x Sub-Micro Servo 3.7g

1 x LED Green

1 x Tactile Button

1 x Resistor 10K Ohm

1 x SparkFun FTDI Basic Breakout - 5V

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// RFM12B Radio

#include <RFM12B.h>

// Sleep

#include <avr/sleep.h>

// You will need to initialize the radio by telling it what ID

// it has and what network it's on

// The NodeID takes values from 1-127, 0 is reserved for sending

// broadcast messages (send to all nodes)

// The Network ID takes values from 0-255

// By default the SPI-SS line used is D10 on Atmega328.

// You can change it by calling .SetCS(pin) where pin can be {8,9,10}

// Network ID used for this unit

#define NODEID 2

// The network ID we are on

#define NETWORKID 99

// The node ID we're sending to

#define GATEWAYID 1

// # of ms to wait for an ack

#define ACK_TIME 50

// Serial

#define SERIAL_BAUD 115200

// Encryption is OPTIONAL

// to enable encryption you will need to:

// - provide a 16-byte encryption KEY (same on all nodes that talk encrypted)

// - to call .Encrypt(KEY) to start encrypting

// - to stop encrypting call .Encrypt(NULL)

uint8_t KEY[] = "ABCDABCDABCDABCD";

// Wait this many ms between sending packets

int interPacketDelay = 50;

// Input

char input = 0;

// Need an instance of the RFM12B Radio Module

RFM12B radio;

// Send Size

byte sendSize = 0;

// Payload

char payload[100];

// Request ACK

bool requestACK = false;

// LED

int iLED = 9;

// The number of the Tactile Button pin

int iTButton = 6;

// Variable for reading the button status

int TButtonState = 0;

// The previous reading from the input pin

int lastTButtonState = LOW;

// The following variables are unsigned longs

// because the time, measured in

// milliseconds, will quickly become a bigger

// number than can be stored in an int.

// The last time the output pin was toggled

unsigned long lastDebounceTime = 0;

// The debounce time; increase if the output flickers

unsigned long debounceDelay = 50;

// String

String zzzzzz = "";

int iSER = 0;

// Software Version Information

String sver = "8-02";

void loop()

{

// Tactile Button

isTButton();

// is RFM12B Radio

isRFM12BRadio();

// Inter Packet Delay

delay(interPacketDelay);

}

getRFM12BRadio.ino

// RFM12B Radio

void isSetupRFM12BRadio(){

// RFM12B Radio

radio.Initialize(NODEID, RF12_433MHZ, NETWORKID);

// Encryption

radio.Encrypt(KEY);

// Sleep right away to save power

radio.Sleep();

// Transmitting

Serial.println("Transmitting...\n\n");

}

// is RFM12 BRadio

void isRFM12BRadio(){

// zzzzzz ""

zzzzzz = "";

// zzzzz = "<SER|" + iSER + "|*";

zzzzzz = "<SER|";

zzzzzz = zzzzzz + iSER;

zzzzzz = zzzzzz + "|*";

// sendSize Length

sendSize = zzzzzz.length();

// sendSize

payload[sendSize];

// sendSize, charAt

for(byte i = 0; i < sendSize+1; i++){

payload[i] = zzzzzz.charAt(i);

}

// payload

Serial.print(payload);

// Request ACK

requestACK = sendSize;

// Wakeup

radio.Wakeup();

// Turn the LED on HIGH

digitalWrite( iLED , HIGH);

// Send

radio.Send(GATEWAYID, payload, sendSize, requestACK);

// Request ACK

if (requestACK)

{

Serial.print(" - waiting for ACK...");

if (waitForAck()){

Serial.print("Ok!");

}

else Serial.print("nothing...");

}

// Turn the LED on LOW

digitalWrite( iLED , LOW);

// Sleep

radio.Sleep();

// Serial

Serial.println();

}

// Wait a few milliseconds for proper ACK, return true if received

static bool waitForAck(){

// Now

long now = millis();

// ACK

while (millis() - now <= ACK_TIME){

if (radio.ACKReceived(GATEWAYID)){

return true;

}

}

return false;

}

getTButton.ino

// Tactile Button

void isTButton(){

// Read the state of the Button value:

int reading = digitalRead(iTButton);

// Check to see if you just pressed the TButton

// (i.e. the input went from LOW to HIGH), and you've waited long enough

// since the last press to ignore any noise:

// If the TButton changed, due to noise or pressing:

if (reading != lastTButtonState) {

// Reset the debouncing timer

lastDebounceTime = millis();

}

if ((millis() - lastDebounceTime) > debounceDelay) {

// Whatever the reading is at, it's been there for

// longer than the debounce

// delay, so take it as the actual current state:

// if the button state has changed:

if (reading != TButtonState) {

TButtonState = reading;

// Check if the TButton is pressed. If it is, the TButtonState is HIGH:

if (TButtonState == HIGH) {

iSER = 1;

} else {

iSER = 0;

}

}

}

// Save the reading. Next time through the loop,

// it'll be the lastTButtonState:

lastTButtonState = reading;

}

setup.ino

// Setup

void setup(){

// Serial

Serial.begin(SERIAL_BAUD);

// LED

pinMode( iLED , OUTPUT);

// Initialize the Button pin as an input

pinMode(iTButton, INPUT);

// Setup RFM12B Radio

isSetupRFM12BRadio();

}

Moteino R2 (Receive)

TR0 – Digital 2

LED – Digital 9

TR1 – Digital 10

TR2 – Digital 11

TR3 – Digital 12

TR4 – Digital 13

VIN – +5V

VIN – +3.3V

GND – GND

—

DL2310Mk03Mkpr.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #8: Servo - Radio Frequency - Mk02

6-02

Receive

DL2310Mk03pr.ino

2 x Moteino R2 (RFM12B)

1 x Pololu Adjustable Boost Regulator 2.5-9.5V

2 x Lithium Ion Battery - 1Ah

1 x Sub-Micro Servo 3.7g

1 x LED Green

1 x Tactile Button

1 x Resistor 10K Ohm

1 x SparkFun FTDI Basic Breakout - 5V

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// RFM12B Radio

#include <RFM12B.h>

// Servo

#include <Servo.h>

// You will need to initialize the radio by telling it what ID

// it has and what network it's on

// The NodeID takes values from 1-127, 0 is reserved for sending

// broadcast messages (send to all nodes)

// The Network ID takes values from 0-255

// By default the SPI-SS line used is D10 on Atmega328.

// You can change it by calling .SetCS(pin) where pin can be {8,9,10}

// Network ID used for this unit

#define NODEID 1

// The network ID we are on

#define NETWORKID 99

// Serial

#define SERIAL_BAUD 115200

// Encryption is OPTIONAL

// to enable encryption you will need to:

// - provide a 16-byte encryption KEY (same on all nodes that talk encrypted)

// - to call .Encrypt(KEY) to start encrypting

// - to stop encrypting call .Encrypt(NULL)

uint8_t KEY[] = "ABCDABCDABCDABCD";

// Need an instance of the RFM12B Radio Module

RFM12B radio;

// Message

String msg = "";

// Servo

int iSER = 0;

String sSER = "";

int firstClosingBracket = 0;

// LED

int iLED = 9;

int iLEDG = 7;

// Servo control

Servo serv;

const int pinServo = 6;

// Software Version Information

String sver = "8-02";

void loop() {

// is RFM12B Radio

isRFM12BRadio();

}

getRFM12BRadio.ino

// RFM12B Radio

void isSetupRFM12BRadio()

{

// RFM12B Radio

radio.Initialize(NODEID, RF12_433MHZ, NETWORKID);

// Encryption

radio.Encrypt(KEY);

// Transmitting

Serial.println("Listening...");

}

// is RFM12 BRadio

void isRFM12BRadio()

{

// Receive

if (radio.ReceiveComplete())

{

// CRC Pass

if (radio.CRCPass())

{

// Serial

Serial.print('[');

Serial.print(radio.GetSender());

Serial.print("] ");

// Message

msg = "";

// Can also use radio.GetDataLen() if you don't like pointers

for (byte i = 0; i < *radio.DataLen; i++)

{

Serial.print((char)radio.Data[i]);

msg = msg + (char)radio.Data[i];

}

// Turn the LED on HIGH

digitalWrite( iLED , HIGH);

// Servo

isServo();

// ACK Requested

if (radio.ACKRequested())

{

// Send ACK

radio.SendACK();

Serial.print(" - ACK Sent");

}

// Turn the LED on LOW

digitalWrite( iLED , LOW);

}

else

{

// BAD-CRC

Serial.print("BAD-CRC");

}

// Serial

Serial.println();

}

}

getServo.ino

// Servo

void isServo(){

// Message

//Serial.println( msg );

// msg = "<SER|0|*";

firstClosingBracket = 0;

// "<SER|"

firstClosingBracket = msg.indexOf('|');

//Serial.println( msg );

msg.remove(0, 5);

//Serial.println( msg );

// Servo

firstClosingBracket = msg.indexOf('|');

sSER = msg;

sSER.remove(firstClosingBracket);

//Serial.println( sSER );

iSER = sSER.toInt();

//Serial.println( iSER );

int x = iSER;

if (x == 1) {

digitalWrite(iLEDG, HIGH);

// Set servo to unlock

serv.write( 0 );

delay(15);

} else {

digitalWrite(iLEDG, LOW);

// Set servo to lock

serv.write( 90 );

delay(15);

}

}

setup.ino

// Setup

void setup()

{

// Serial

Serial.begin(SERIAL_BAUD);

// LED

pinMode( iLED , OUTPUT);

pinMode( iLEDG , OUTPUT);

// Attach Servo

serv.attach( pinServo );

// RFM12B Radio

isSetupRFM12BRadio();

}

——

People can contact us: https://www.donluc.com/?page_id=1927

Teacher, Instructor, E-Mentor, R&D and Consulting

- Programming Language

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi, Arm, Silicon Labs, Espressif, Etc…)

- IoT

- Wireless (Radio Frequency, Bluetooth, WiFi, Etc…)

- Robotics

- Automation

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Machine Learning

- Artificial Intelligence (AI)

- RTOS

- eHealth Sensors, Biosensor, and Biometric

- Research & Development (R & D)

- Consulting

Follow Us

Luc Paquin – Curriculum Vitae – 2023

https://www.donluc.com/luc/

Web: https://www.donluc.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/@thesass2063

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

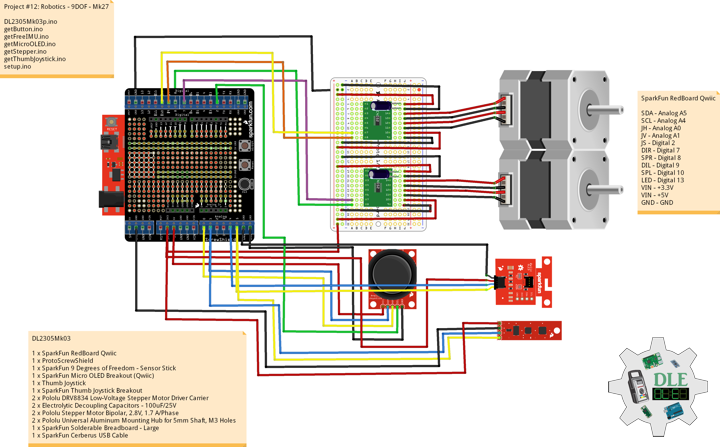

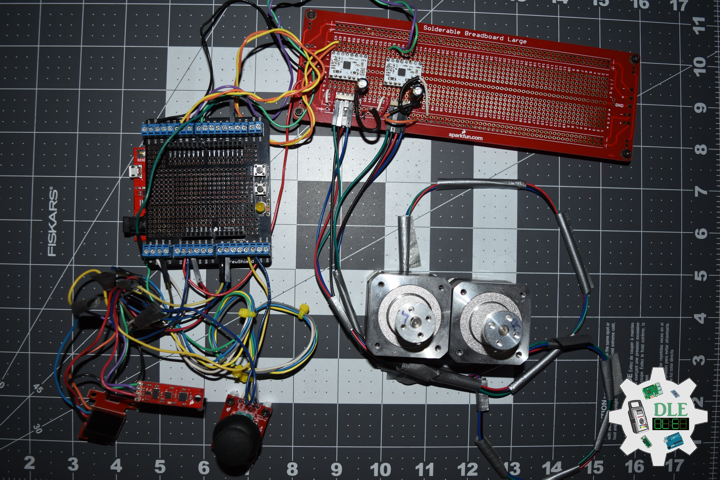

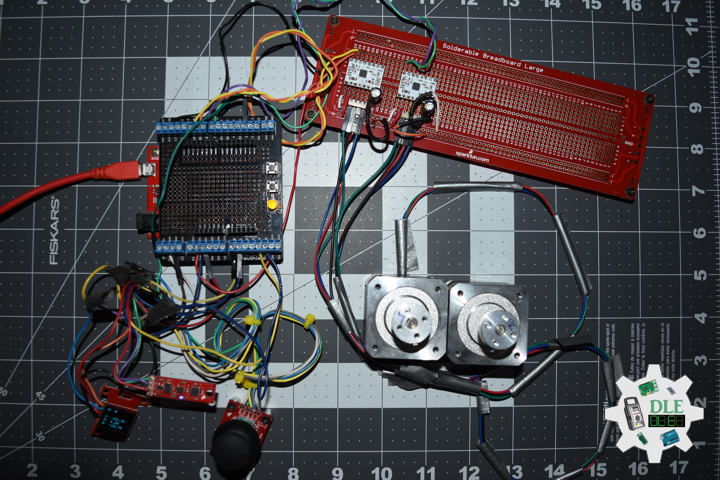

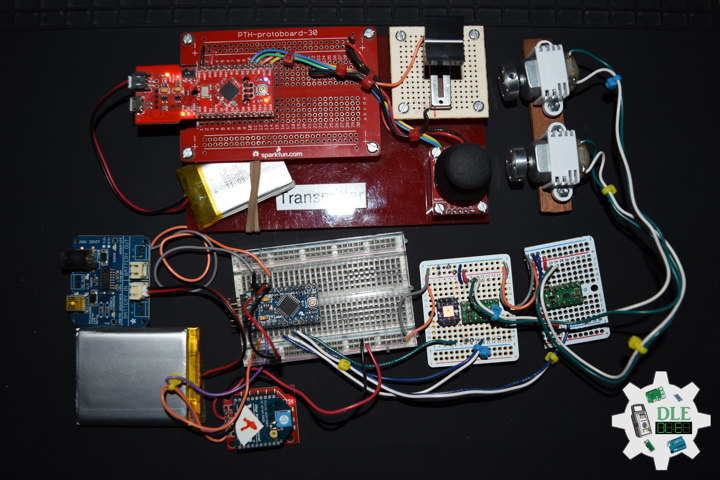

Project #12: Robotics – 9DOF – Mk27

——

#DonLucElectronics #DonLuc #Robotics #Magnetometer #Accelerometer #Gyroscope #MicroOLED # #Arduino #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——

SparkFun 9 Degrees of Freedom – Sensor Stick

The SparkFun 9DOF Sensor Stick is a very small sensor board with 9 degrees of freedom. It includes the ADXL345 accelerometer, the HMC5883L magnetometer, and the ITG-3200 MEMS gyro. The “Stick” has a simple I2C interface and a mounting hole for attaching it to your project. Also, the board is a mere allowing it to be easily mounted in just about any application.

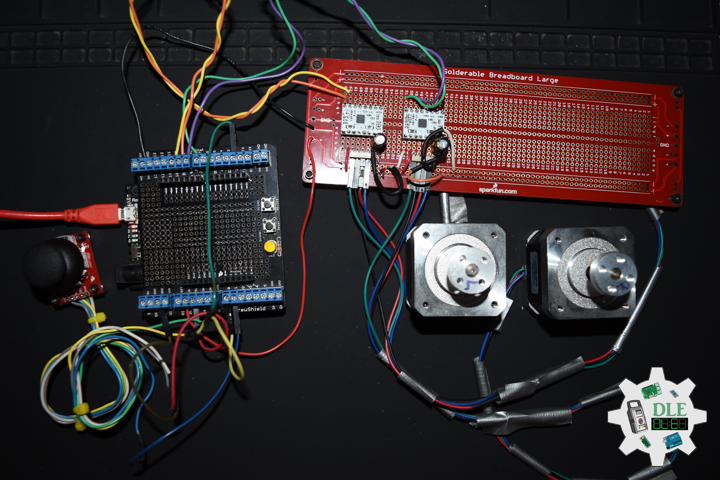

DL2305Mk03

1 x SparkFun RedBoard Qwiic

1 x ProtoScrewShield

1 x SparkFun 9 Degrees of Freedom – Sensor Stick

1 x SparkFun Micro OLED Breakout (Qwiic)

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors – 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard – Large

1 x SparkFun Cerberus USB Cable

SparkFun RedBoard Qwiic

SDA – Analog A5

SCL – Analog A4

JH – Analog A0

JV – Analog A1

JS – Digital 2

DIR – Digital 7

SPR – Digital 8

DIL – Digital 9

SPL – Digital 10

LED – Digital 13

VIN – +3.3V

VIN – +5V

GND – GND

——

DL2305Mk03p.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - 9DOF - Mk27

12-27

DL2305Mk03p.ino

1 x SparkFun RedBoard Qwiic

1 x ProtoScrewShield

1 x SparkFun 9 Degrees of Freedom - Sensor Stick

1 x SparkFun Micro OLED Breakout (Qwiic)

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors - 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard - Large

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// Arduino

#include <Arduino.h>

// DRV8834 Stepper Motor Driver

#include <BasicStepperDriver.h>

#include <MultiDriver.h>

// Wire communicate with I2C / TWI devices

#include <Wire.h>

// SparkFun Micro OLED

#include <SFE_MicroOLED.h>

// Accelerometer

#include <ADXL345.h>

// Magnetometer

#include <HMC58X3.h>

// MEMS Gyroscope

#include <ITG3200.h>

// Debug

#include "DebugUtils.h"

// FreeIMU

#include <CommunicationUtils.h>

#include <FreeIMU.h>

// DRV8834 Stepper Motor Driver

// Stepper motor steps per revolution.

// Most steppers are 200 steps or 1.8 degrees/step

#define MOTOR_STEPS 200

// Target RPM for X axis stepper motor

#define MOTOR_X_RPM 800

// Target RPM for Y axis stepper motor

#define MOTOR_Y_RPM 800

// Since microstepping is set externally,

// make sure this matches the selected mode

// If it doesn't, the motor will move at a

// different RPM than chosen

// 1=full step, 2=half step etc.

#define MICROSTEPS 1

// X Stepper motor

#define DIR_X 7

#define STEP_X 8

// Y Stepper motor

#define DIR_Y 9

#define STEP_Y 10

// BasicStepperDriver

BasicStepperDriver stepperX(MOTOR_STEPS, DIR_X, STEP_X);

BasicStepperDriver stepperY(MOTOR_STEPS, DIR_Y, STEP_Y);

// Pick one of the two controllers below

// each motor moves independently

MultiDriver controller(stepperX, stepperY);

// Joystick

#define JH A0

#define JV A1

#define JS 2

// Variable for reading the button

int JSState = 0;

// Adjusted Value

int adjustedValue = 0;

int adjustedValue2 = 0;

// LED Yellow

int iLED = 13;

// SparkFun Micro OLED

#define PIN_RESET 9

#define DC_JUMPER 1

// I2C declaration

MicroOLED oled(PIN_RESET, DC_JUMPER);

// Set the FreeIMU object

FreeIMU my3IMU = FreeIMU();

// Yaw Pitch Roll

float ypr[3];

float Yaw = 0;

float Pitch = 0;

float Roll = 0;

// Software Version Information

String sver = "12-27";

void loop() {

// Button

isButton();

// Joystick

isThumbJoystick();

// Stepper

isStepper();

// isFreeIMU

isFreeIMU();

// Micro OLED

isMicroOLED();

}

getButton.ino

// Button

// Button Setup

void isButtonSetup() {

// Make the button line an input

pinMode(JS, INPUT_PULLUP);

// Initialize digital pin iLED as an output

pinMode(iLED, OUTPUT);

}

// Button

void isButton(){

// Read the state of the button

JSState = digitalRead(JS);

// Check if the button is pressed.

// If it is, the JSState is HIGH:

if (JSState == HIGH) {

// Button

// Turn the LED on HIGH

digitalWrite(iLED, HIGH);

} else {

// Button

// Turn the LED on LOW

digitalWrite(iLED, LOW);

}

}

getFreeIMU.ino

// FreeIMU

// isFreeIMUSetup

void isFreeIMUSetup(){

// Pause

delay(5);

// Initialize IMU

my3IMU.init();

// Pause

delay(5);

}

// isFreeIMU

void isFreeIMU(){

// FreeIMU

// Yaw Pitch Roll

my3IMU.getYawPitchRoll(ypr);

// Yaw

Yaw = ypr[0];

// Pitch

Pitch = ypr[1];

// Roll

Roll = ypr[2];

}

getMicroOLED.ino

// SparkFun Micro OLED

// Micro OLED Setup

void isMicroOLEDSetup() {

// Initialize the OLED

oled.begin();

// Clear the display's internal memory

oled.clear(ALL);

// Display what's in the buffer (Splash Screen SparkFun)

oled.display();

// Delay 1000 ms

delay(1000);

// Clear the buffer.

oled.clear(PAGE);

}

// Micro OLED

void isMicroOLED() {

// Text Display FreeIMU

// Clear the display

oled.clear(PAGE);

// Set cursor to top-left

oled.setCursor(0, 0);

// Set font to type 0

oled.setFontType(0);

// Horizontal

oled.print("H: ");

oled.print( adjustedValue );

// Vertical

oled.setCursor(0, 11);

oled.print("V: ");

oled.print( adjustedValue2 );

// Yaw

oled.setCursor(0, 21);

oled.print("Y: ");

oled.print(Yaw);

// Pitch

oled.setCursor(0, 31);

oled.print("P: ");

oled.print(Pitch);

// Roll

oled.setCursor(0, 41);

oled.print("R: ");

oled.print(Roll);

oled.display();

}

getStepper.ino

// Stepper

// isStepperSetup

void isStepperSetup() {

// Set stepper target motors RPM.

stepperX.begin(MOTOR_X_RPM, MICROSTEPS);

stepperY.begin(MOTOR_Y_RPM, MICROSTEPS);

}

// Stepper

void isStepper() {

// Stepper => Controller rotate

controller.rotate(adjustedValue, adjustedValue2);

}

getThumbJoystick.ino

// Thumb Joystick

void isThumbJoystick() {

// Joystick JH

// Horizontal

// Joystick Pot Values JH

int potValue = analogRead(JH);

int potValues = 0;

// Adjusted Value

potValues = map(potValue, 0, 1023, 1000, -1000);

if (potValues > 300) {

adjustedValue = potValues;

} else if (potValues < -300) {

adjustedValue = potValues;

} else {

adjustedValue = 0;

}

// Joystick JV

// Vertical

// Joystick Pot Values JV

int potValue2 = analogRead(JV);

int potValues2 = 0;

// Adjusted Value2

potValues2 = map(potValue2, 0, 1023, 1000, -1000);

if (potValues2 > 300) {

adjustedValue2 = potValues2;

} else if (potValues2 < -300) {

adjustedValue2 = potValues2;

} else {

adjustedValue2 = 0;

}

}

setup.ino

// Setup

void setup()

{

// Wire communicate with I2C / TWI devices

Wire.begin();

// Setup Micro OLED

isMicroOLEDSetup();

// isFreeIMUSetup

isFreeIMUSetup();

// Button Setup

isButtonSetup();

// DRV8834 Stepper Motor Driver

isStepperSetup();

}

——

People can contact us: https://www.donluc.com/?page_id=1927

Technology Experience

- Programming Language

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi,Espressif, etc…)

- IoT

- Wireless (Radio Frequency, Bluetooth, WiFi, Etc…)

- Robotics

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Machine Learning

- RTOS

- Research & Development (R & D)

Instructor, E-Mentor, STEAM, and Arts-Based Training

- Programming Language

- IoT

- PIC Microcontrollers

- Arduino

- Raspberry Pi

- Espressif

- Robotics

Follow Us

Luc Paquin – Curriculum Vitae – 2023

https://www.donluc.com/luc/

Web: https://www.donluc.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/@thesass2063

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

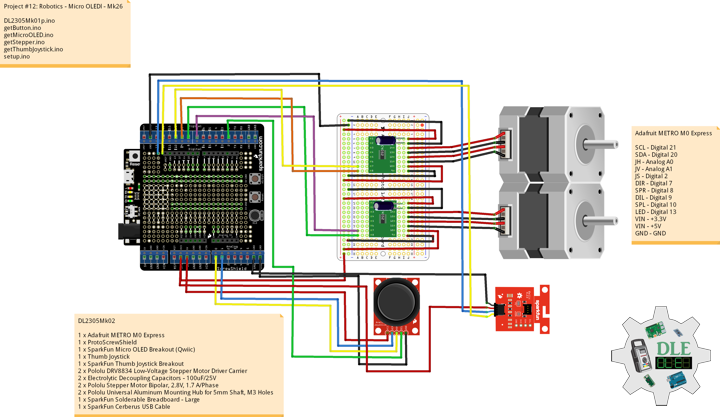

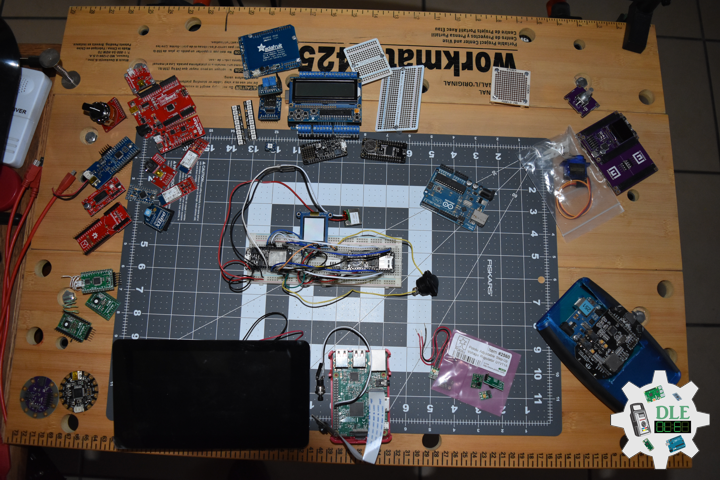

Project #12: Robotics – Micro OLED – Mk26

——

#DonLucElectronics #DonLuc #Robotics #MicroOLED #AdafruitMETROM0Express #Arduino #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——-

Micro OLED

Micro OLED displays are silicon-based OLED display that use a monocrystalline silicon wafer as the actively driven backplane, so it is easier to achieve high PPI (Pixel Density), a high degree of integration, and small size. This ensures they are easy to carry, have good anti-seismic performance, and have ultra-low power consumption.

DL2305Mk02

1 x Adafruit METRO M0 Express

1 x ProtoScrewShield

1 x SparkFun Micro OLED Breakout (Qwiic)

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors – 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard – Large

1 x SparkFun Cerberus USB Cable

Adafruit METRO M0 Express

SCL – Digital 21

SDA – Digital 20

JH – Analog A0

JV – Analog A1

JS – Digital 2

DIR – Digital 7

SPR – Digital 8

DIL – Digital 9

SPL – Digital 10

LED – Digital 13

VIN – +3.3V

VIN – +5V

GND – GND

——

DL2305Mk02p.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Micro OLED - Mk26

12-26

DL2305Mk02p.ino

1 x Adafruit METRO M0 Express

1 x ProtoScrewShield

1 x SparkFun Micro OLED Breakout (Qwiic)

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors - 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard - Large

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// Arduino

#include <Arduino.h>

// DRV8834 Stepper Motor Driver

#include <BasicStepperDriver.h>

#include <MultiDriver.h>

// Wire communicate with I2C / TWI devices

#include <Wire.h>

// SparkFun Micro OLED

#include <SFE_MicroOLED.h>

// DRV8834 Stepper Motor Driver

// Stepper motor steps per revolution.

// Most steppers are 200 steps or 1.8 degrees/step

#define MOTOR_STEPS 200

// Target RPM for X axis stepper motor

#define MOTOR_X_RPM 800

// Target RPM for Y axis stepper motor

#define MOTOR_Y_RPM 800

// Since microstepping is set externally,

// make sure this matches the selected mode

// If it doesn't, the motor will move at a

// different RPM than chosen

// 1=full step, 2=half step etc.

#define MICROSTEPS 1

// X Stepper motor

#define DIR_X 7

#define STEP_X 8

// Y Stepper motor

#define DIR_Y 9

#define STEP_Y 10

// BasicStepperDriver

BasicStepperDriver stepperX(MOTOR_STEPS, DIR_X, STEP_X);

BasicStepperDriver stepperY(MOTOR_STEPS, DIR_Y, STEP_Y);

// Pick one of the two controllers below

// each motor moves independently

MultiDriver controller(stepperX, stepperY);

// Joystick

#define JH A0

#define JV A1

#define JS 2

// Variable for reading the button

int JSState = 0;

// Adjusted Value

int adjustedValue = 0;

int adjustedValue2 = 0;

// LED Yellow

int iLED = 13;

// SparkFun Micro OLED

#define PIN_RESET 9

#define DC_JUMPER 1

// I2C declaration

MicroOLED oled(PIN_RESET, DC_JUMPER);

// Software Version Information

String sver = "12-26";

void loop() {

// Button

isButton();

// Joystick

isThumbJoystick();

// Stepper

isStepper();

// Micro OLED

isMicroOLED();

}

getButton.ino

// Button

// Button Setup

void isButtonSetup() {

// Make the button line an input

pinMode(JS, INPUT_PULLUP);

// Initialize digital pin iLED as an output

pinMode(iLED, OUTPUT);

}

// Button

void isButton(){

// Read the state of the button

JSState = digitalRead(JS);

// Check if the button is pressed.

// If it is, the JSState is HIGH:

if (JSState == HIGH) {

// Button

// Turn the LED on HIGH

digitalWrite(iLED, HIGH);

} else {

// Button

// Turn the LED on LOW

digitalWrite(iLED, LOW);

}

}

getMicroOLED.ino

// SparkFun Micro OLED

// Setup Micro OLED

void isMicroOLEDSetup() {

// Initialize the OLED

oled.begin();

// Clear the display's internal memory

oled.clear(ALL);

// Display what's in the buffer (Splash Screen SparkFun)

oled.display();

// Delay 1000 ms

delay(1000);

// Clear the buffer.

oled.clear(PAGE);

}

// Micro OLED

void isMicroOLED() {

// Text Display FreeIMU

// Clear the display

oled.clear(PAGE);

// Set cursor to top-left

oled.setCursor(0, 0);

// Set font to type 0

oled.setFontType(0);

// Horizontal

oled.print("Horizontal");

// Horizontal

oled.setCursor(0, 13);

oled.print( adjustedValue );

// Vertical

oled.setCursor(0, 24);

oled.print("Vertical");

// Vertical

oled.setCursor(0, 37);

oled.print( adjustedValue2 );

oled.display();

}

getStepper.ino

// Stepper

// isStepperSetup

void isStepperSetup() {

// Set stepper target motors RPM.

stepperX.begin(MOTOR_X_RPM, MICROSTEPS);

stepperY.begin(MOTOR_Y_RPM, MICROSTEPS);

}

// Stepper

void isStepper() {

// Stepper => Controller rotate

controller.rotate(adjustedValue, adjustedValue2);

}

getThumbJoystick.ino

// Thumb Joystick

void isThumbJoystick() {

// Joystick JH

// Horizontal

// Joystick Pot Values JH

int potValue = analogRead(JH);

int potValues = 0;

// Adjusted Value

potValues = map(potValue, 0, 1023, 1000, -1000);

if (potValues > 300) {

adjustedValue = potValues;

} else if (potValues < -300) {

adjustedValue = potValues;

} else {

adjustedValue = 0;

}

// Joystick JV

// Vertical

// Joystick Pot Values JV

int potValue2 = analogRead(JV);

int potValues2 = 0;

// Adjusted Value2

potValues2 = map(potValue2, 0, 1023, 1000, -1000);

if (potValues2 > 300) {

adjustedValue2 = potValues2;

} else if (potValues2 < -300) {

adjustedValue2 = potValues2;

} else {

adjustedValue2 = 0;

}

}

setup.ino

// Setup

void setup()

{

// Wire communicate with I2C / TWI devices

Wire.begin();

// Setup Micro OLED

isMicroOLEDSetup();

// Button Setup

isButtonSetup();

// DRV8834 Stepper Motor Driver

isStepperSetup();

}

——

People can contact us: https://www.donluc.com/?page_id=1927

Technology Experience

- Programming Language

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi,Espressif, etc…)

- IoT

- Wireless (Radio Frequency, Bluetooth, WiFi, Etc…)

- Robotics

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Machine Learning

- RTOS

- Research & Development (R & D)

Instructor, E-Mentor, STEAM, and Arts-Based Training

- Programming Language

- IoT

- PIC Microcontrollers

- Arduino

- Raspberry Pi

- Espressif

- Robotics

Follow Us

Luc Paquin – Curriculum Vitae – 2023

https://www.donluc.com/luc/

Web: https://www.donluc.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/@thesass2063

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

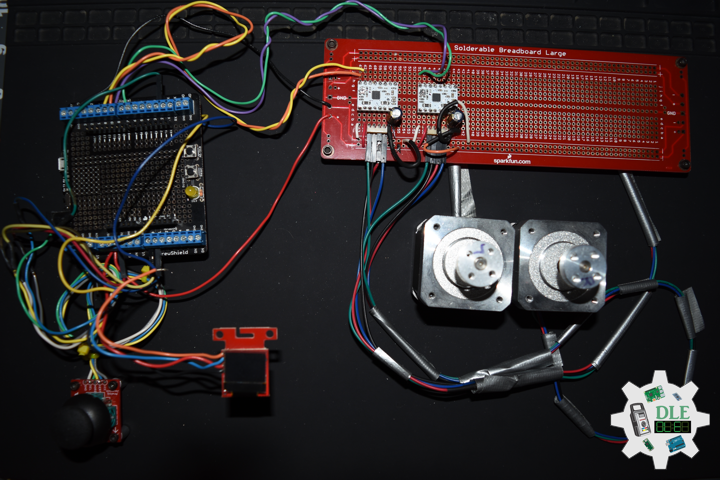

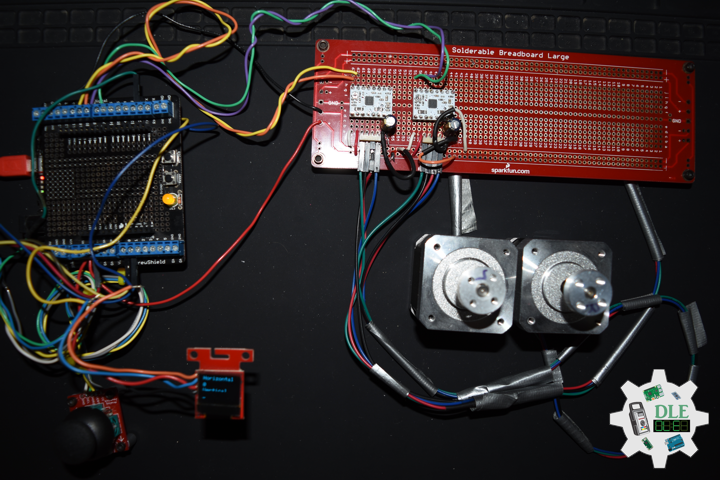

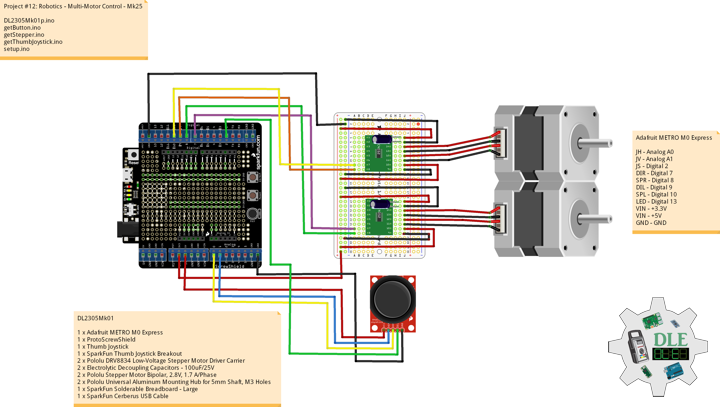

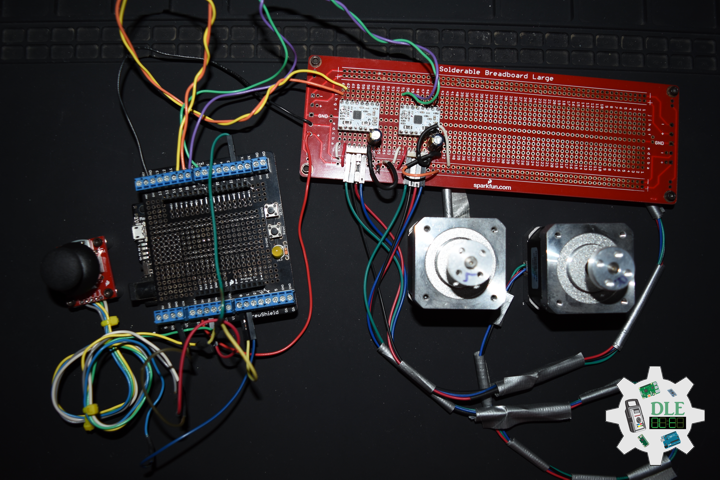

Project #12: Robotics – Multi-Motor Control – Mk25

——

#DonLucElectronics #DonLuc #Robotics #MultiMotorControl #AdafruitMETROM0Express #Arduino #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——

Multi-Motor Control

In order to synchronize the multi-motor system, a novel method for this system based on embedded control terminal. A controller of the strategy with the function of synchronous control is also completed. According to the requirements of this system, a distributed control structure which based on Hierarchical Approach is chosen. The hardware platform of this structure is composed of embedded control terminal motor could be driven independently. The experiment results verified that the multi-motor system is reliable, the control strategy is rational applied this multi-motor system has better dynamic response and higher reliability.

DL2305Mk01

1 x Adafruit METRO M0 Express

1 x ProtoScrewShield

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors – 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard – Large

1 x SparkFun Cerberus USB Cable

Adafruit METRO M0 Express

JH – Analog A0

JV – Analog A1

JS – Digital 2

DIR – Digital 7

SPR – Digital 8

DIL – Digital 9

SPL – Digital 10

LED – Digital 13

VIN – +3.3V

VIN – +5V

GND – GND

——

DL2305Mk01p.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Multi-Motor Control - Mk25

12-25

DL2305Mk01p.ino

1 x Adafruit METRO M0 Express

1 x ProtoScrewShield

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

2 x Pololu DRV8834 Low-Voltage Stepper Motor Driver Carrier

2 x Electrolytic Decoupling Capacitors - 100uF/25V

2 x Pololu Stepper Motor Bipolar, 2.8V, 1.7 A/Phase

2 x Pololu Universal Aluminum Mounting Hub for 5mm Shaft, M3 Holes

1 x SparkFun Solderable Breadboard - Large

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// Arduino

#include <Arduino.h>

// DRV8834 Stepper Motor Driver

#include <BasicStepperDriver.h>

#include <MultiDriver.h>

// DRV8834 Stepper Motor Driver

// Stepper motor steps per revolution.

// Most steppers are 200 steps or 1.8 degrees/step

#define MOTOR_STEPS 200

// Target RPM for X axis stepper motor

#define MOTOR_X_RPM 800

// Target RPM for Y axis stepper motor

#define MOTOR_Y_RPM 800

// Since microstepping is set externally,

// make sure this matches the selected mode

// If it doesn't, the motor will move at a

// different RPM than chosen

// 1=full step, 2=half step etc.

#define MICROSTEPS 1

// X Stepper motor

#define DIR_X 7

#define STEP_X 8

// Y Stepper motor

#define DIR_Y 9

#define STEP_Y 10

// BasicStepperDriver

BasicStepperDriver stepperX(MOTOR_STEPS, DIR_X, STEP_X);

BasicStepperDriver stepperY(MOTOR_STEPS, DIR_Y, STEP_Y);

// Pick one of the two controllers below

// each motor moves independently

MultiDriver controller(stepperX, stepperY);

// Joystick

#define JH A0

#define JV A1

#define JS 2

// Variable for reading the button

int JSState = 0;

// Adjusted Value

int adjustedValue = 0;

int adjustedValue2 = 0;

// LED Yellow

int iLED = 13;

// Software Version Information

String sver = "12-25";

void loop() {

// Button

isButton();

// Joystick

isThumbJoystick();

// Stepper

isStepper();

}

getButton.ino

// Button

// Button Setup

void isButtonSetup() {

// Make the button line an input

pinMode(JS, INPUT_PULLUP);

// Initialize digital pin iLED as an output

pinMode(iLED, OUTPUT);

}

// Button

void isButton(){

// Read the state of the button

JSState = digitalRead(JS);

// Check if the button is pressed.

// If it is, the JSState is HIGH:

if (JSState == HIGH) {

// Button

// Turn the LED on HIGH

digitalWrite(iLED, HIGH);

} else {

// Button

// Turn the LED on LOW

digitalWrite(iLED, LOW);

}

}

getStepper.ino

// Stepper

// isStepperSetup

void isStepperSetup() {

// Set stepper target motors RPM.

stepperX.begin(MOTOR_X_RPM, MICROSTEPS);

stepperY.begin(MOTOR_Y_RPM, MICROSTEPS);

}

// Stepper

void isStepper() {

// Stepper => Controller rotate

controller.rotate(adjustedValue, adjustedValue2);

}

getThumbJoystick.ino

// Thumb Joystick

void isThumbJoystick() {

// Joystick JH

// Horizontal

// Joystick Pot Values JH

int potValue = analogRead(JH);

int potValues = 0;

// Adjusted Value

potValues = map(potValue, 0, 1023, 1000, -1000);

if (potValues > 300) {

adjustedValue = potValues;

} else if (potValues < -300) {

adjustedValue = potValues;

} else {

adjustedValue = 0;

}

// Joystick JV

// Vertical

// Joystick Pot Values JV

int potValue2 = analogRead(JV);

int potValues2 = 0;

// Adjusted Value2

potValues2 = map(potValue2, 0, 1023, 1000, -1000);

if (potValues2 > 300) {

adjustedValue2 = potValues2;

} else if (potValues2 < -300) {

adjustedValue2 = potValues2;

} else {

adjustedValue2 = 0;

}

}

setup.ino

// Setup

void setup()

{

// Button Setup

isButtonSetup();

// DRV8834 Stepper Motor Driver

isStepperSetup();

}

——

People can contact us: https://www.donluc.com/?page_id=1927

Technology Experience

- Programming Language

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi,Espressif, etc…)

- IoT

- Wireless (Radio Frequency, Bluetooth, WiFi, Etc…)

- Robotics

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Machine Learning

- RTOS

- Research & Development (R & D)

Instructor, E-Mentor, STEAM, and Arts-Based Training

- Programming Language

- IoT

- PIC Microcontrollers

- Arduino

- Raspberry Pi

- Espressif

- Robotics

Follow Us

Luc Paquin – Curriculum Vitae – 2023

https://www.donluc.com/luc/

Web: https://www.donluc.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/@thesass2063

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

Welcome to The Alpha Geek Blog – 2012

——

#DonLucElectronics #DonLuc #Programming #Electronics #Microcontrollers #Consultant

——

——

Back to the electronics world where somebody used to apprentice for years before moving up in the electronics hierarchy, we now have kids that goes for a few weeks to a few months in a famous microcontrollers, and move on to another one to improve their resumé, and that they want to be electronics stars a few short years after they get interested in the trade. This lead to what I saw yesterday on YouTube when a 25 year old ‘Old Timer’ has is own electronics show on YouTube, plainly shows that he cannot handle the job at hand, and even worse does not even demonstrate good manual skill at the basic components work for the programming he demonstrates. The later is a trait that you see often nowadays on electronics show, and I assume that they do not teach basic techniques, or worse that they do, but most people do not bother learning and practicing them properly.

I guess that I am ranting again and boring you all, and that what was supposed to be a very short post is turning into a long one, but I firmly believe that experience and basic skills takes time to learn, and that there are no shortcuts to attain them both. I noticed the same trend in my professional life as a programmer, is that there are so many new things to learn that people are more interested in the technology itself, than in making thing actually do something very well, without the need of the latest technology.

A word of advise to anybody passing by here from an ‘Old Timer’ at many things including life, no matter what your goals are in life, no matter what subject you really feel deeply interested in, please take some time developing the basic skills to achieve your goals. It both takes time and a lot of practice, but when you finally grow up and are finally getting a bit of real life experience under your collar, you will learn to appreciate the fact that you actually know a lot more about the subject at hand than a lot of your contemporaries, and one day you will also learn to be proud of that in itself. By the way, this also applies to people my age, as we are never too old to learn anything new, and experience, no matter how old you are to start with, takes a long time to accumulate. As they would say today, knowledge and experience rules!

Welcome to The Alpha Geek Blog – 2012

After many setback in the past few weeks it is finally the time to launch this video blog. I want to welcome you all and I hope that this technology video blog will be both interesting and helpful.

People can contact us: https://www.donluc.com/?page_id=1927

Technology Experience

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi,Espressif, etc…)

- IoT

- Robotics

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Research & Development (R & D)

- Desktop Applications (Windows, OSX, Linux, Multi-OS, Multi-Tier, etc…)

- Mobile Applications (Android, iOS, Blackberry, Windows Mobile, Windows CE, etc…)

- Web Applications (LAMP, Scripting, Java, ASP, ASP.NET, RoR, Wakanda, etc…)

- Social Media Programming & Integration (Facebook, Twitter, YouTube, Pinterest, etc…)

- Content Management Systems (WordPress, Drupal, Joomla, Moodle, etc…)

- Bulletin Boards (phpBB, SMF, Vanilla, jobberBase, etc…)

- eCommerce (WooCommerce, OSCommerce, ZenCart, PayPal Shopping Cart, etc…)

Instructor and E-Mentor

- IoT

- PIC Microcontrollers

- Arduino

- Raspberry Pi

- Espressif

- Robotics

- DOS, Windows, OSX, Linux, iOS, Android, Multi-OS

- Linux-Apache-PHP-MySQL

Follow Us

J. Luc Paquin – Curriculum Vitae – 2022 English & Español

https://www.jlpconsultants.com/luc/

Web: https://www.donluc.com/

Web: https://www.jlpconsultants.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/channel/UC5eRjrGn1CqkkGfZy0jxEdA

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

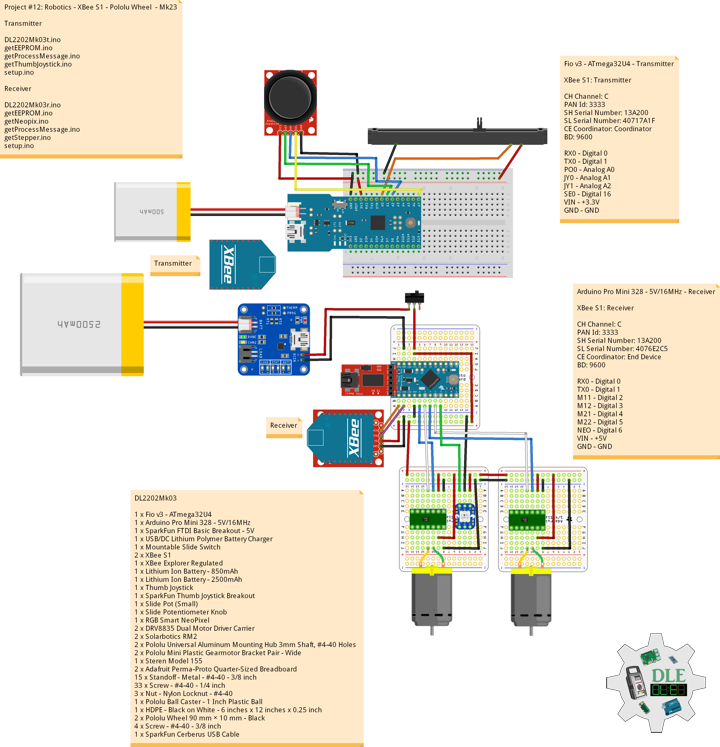

Project #12: Robotics – Pololu Wheel – Mk23

——

#DonLucElectronics #DonLuc #Robotics #Arduino #Fio #ArduinoProMini #XBee #DCMotor #MotorDriver #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——

Pololu Wheel 90 mm × 10 mm – Black

These black plastic wheels have silicone tires and measure 90 mm (3.54 inches) in diameter, and they press-fit onto the 3mm D shafts on many of our motors, including our micro metal gearmotors and our mini plastic gearmotors. Additionally, this wheel is compatible with several of our universal mounting hubs, which can serve as adapters for motors with different shafts. Six mounting holes for #4 or M3 screws make it possible to use the wheel with any of our universal mounting hubs for those screw sizes, enabling these wheels to be used with our larger metal gearmotors and stepper motors. The included silicone tires, which feature horizontal treads for improved traction.

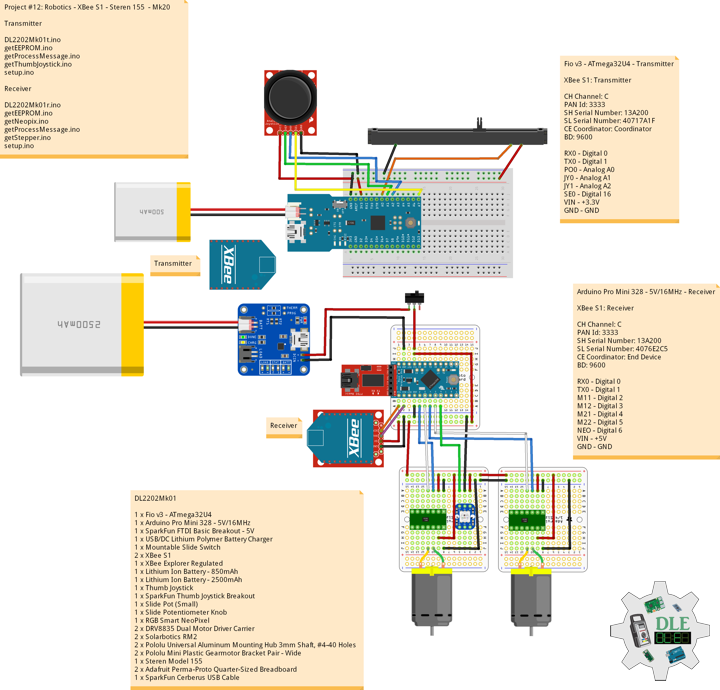

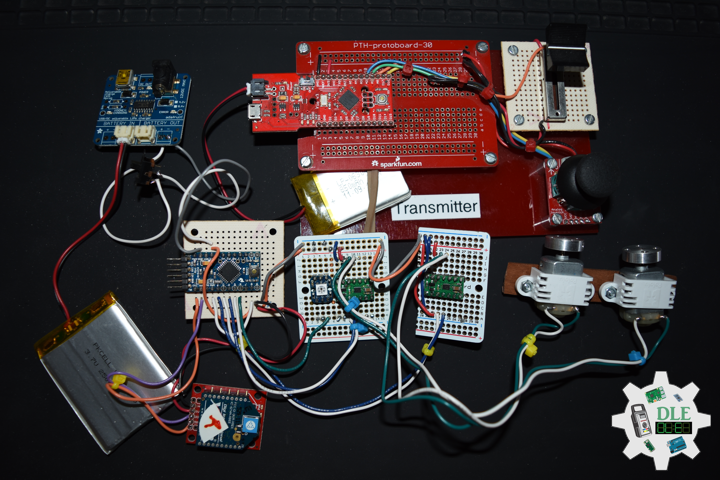

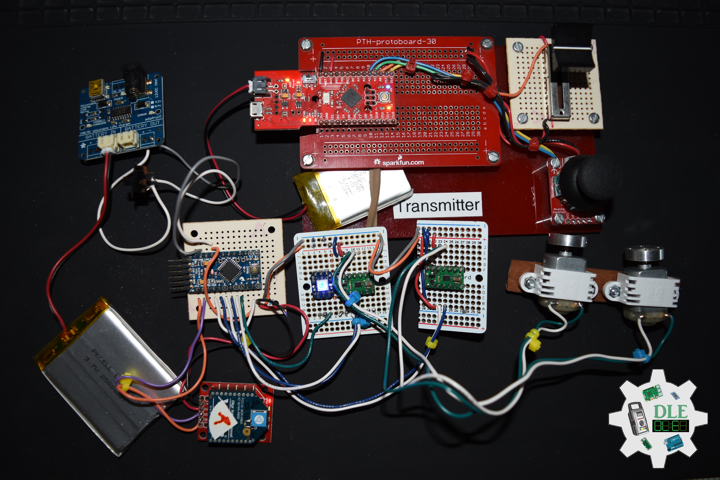

DL2202Mk03

1 x Fio v3 – ATmega32U4

1 x Arduino Pro Mini 328 – 5V/16MHz

1 x SparkFun FTDI Basic Breakout – 5V

1 x USB/DC Lithium Polymer Battery Charger

1 x Mountable Slide Switch

2 x XBee S1

1 x XBee Explorer Regulated

1 x Lithium Ion Battery – 850mAh

1 x Lithium Ion Battery – 2500mAh

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

1 x Slide Pot (Small)

1 x Slide Potentiometer Knob

1 x RGB Smart NeoPixel

2 x DRV8835 Dual Motor Driver Carrier

2 x Solarbotics RM2

2 x Pololu Universal Aluminum Mounting Hub 3mm Shaft, #4-40 Holes

2 x Pololu Mini Plastic Gearmotor Bracket Pair – Wide

1 x Steren Model 155

2 x Adafruit Perma-Proto Quarter-Sized Breadboard

15 x Standoff – Metal – #4-40 – 3/8 inch

33 x Screw – #4-40 – 1/4 inch

3 x Nut – Nylon Locknut – #4-40

1 x Pololu Ball Caster – 1 Inch Plastic Ball

1 x HDPE – Black on White – 6 inches x 12 inches x 0.25 inch

2 x Pololu Wheel 90 mm × 10 mm – Black

4 x Screw – #4-40 – 3/8 inch

1 x SparkFun Cerberus USB Cable

Fio v3 – ATmega32U4 – Transmitter

XBee S1: Transmitter

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 40717A1F

CE Coordinator: Coordinator

BD: 9600

RX0 – Digital 0

TX0 – Digital 1

PO0 – Analog A0

JY0 – Analog A1

JY1 – Analog A2

SE0 – Digital 16

VIN – +3.3V

GND – GND

DL2202Mk03t.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Pololu Wheel - Mk23

02-03

Transmitter

DL2202Mk03t.ino

1 x Fio v3 - ATmega32U4

1 x XBee S1

1 x Lithium Ion Battery - 850mAh

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

1 x Slide Pot (Small)

1 x Slide Potentiometer Knob

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// Communication

unsigned long dTime = 200;

// Slide Pot (Small)

// Select the input pin for the slide pot

// Power

const int iSP1 = A0;

// Power to store the value

int iPower = 0;

// Connections to joystick

// Vertical

const int VERT = A1;

// Horizontal

const int HORIZ = A2;

// Pushbutton

const int SEL = 16;

// Initialize variables for analog and digital values

int vertical;

int horizontal;

int select;

// Software Version Information

// Version

String sver = "12-23t";

// Unit ID Information

// UID

String uid = "";

void loop()

{

// Thumb Joystick

isThumbJoystick();

// Process Message

isProcessMessage();

delay( dTime );

}

getEEPROM.ino

// EEPROM

// is UID

void isUID()

{

// Is Unit ID

// UID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getProcessMessage.ino

// Process Message

// isProcessMessage

void isProcessMessage() {

// Loop through serial buffer

// Print = "<" + vertical + "|" + horizontal + "|" + select + "|" + iValue + "|" + sver + "|" + uid + "*"

Serial1.print( '<' );

Serial1.print( vertical );

Serial1.print( '|' );

Serial1.print( horizontal );

Serial1.print( '|' );

Serial1.print( select );

Serial1.print( '|' );

Serial1.print( iPower );

Serial1.print( '|' );

Serial1.print( sver );

Serial1.print( '|' );

Serial1.print( uid );

Serial1.println( '*' );

}

getThumbJoystick.ino

// Thumb Joystick

void isThumbJoystick() {

// Read all values from the joystick

// Joystick was sitting around 520 for the vertical and horizontal values

// Will be 0-1023

vertical = analogRead(VERT);

// Will be 0-1023

horizontal = analogRead(HORIZ);

// Will be HIGH (1) if not pressed, and LOW (0) if pressed

select = digitalRead(SEL);

// Read the value

// Power be 0-1023

iPower = analogRead( iSP1 );

}

setup.ino

// Setup

void setup()

{

// EEPROM Unit ID

isUID();

// Pause

delay(5);

// Make the SEL line an input

pinMode(SEL, INPUT_PULLUP);

// Open Serial1 port at 9600 baud

Serial1.begin( 9600 );

// Pause

delay(5);

}

——

Arduino Pro Mini 328 – 5V/16MHz – Receiver

XBee S1: Receiver

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 4076E2C5

CE Coordinator: End Device

BD: 9600

RX0 – Digital 0

TX0 – Digital 1

M11 – Digital 2

M12 – Digital 3

M21 – Digital 4

M22 – Digital 5

NEO – Digital 6

VIN – +5V

GND – GND

DL2202Mk03r.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Pololu Wheel - Mk23

02-03

Receiver

DL2202Mk03r.ino

1 x Arduino Pro Mini 328 - 5V/16MHz

1 x SparkFun FTDI Basic Breakout - 5V

1 x XBee S1

1 x XBee Explorer Regulated

1 x USB/DC Lithium Polymer Battery Charger

1 x Mountable Slide Switch

1 x Lithium Ion Battery - 2500mAh

1 x RGB Smart NeoPixel

2 x DRV8835 Dual Motor Driver Carrier

2 x Solarbotics RM2

2 x Pololu Universal Aluminum Mounting Hub 3mm Shaft, #4-40 Holes

2 x Pololu Mini Plastic Gearmotor Bracket Pair - Wide

1 x Steren Model 155

2 x Adafruit Perma-Proto Quarter-Sized Breadboard

15 x Standoff - Metal - #4-40 - 3/8 inch

33 x Screw - #4-40 - 1/4 inch

3 x Nut - Nylon Locknut - #4-40

1 x Pololu Ball Caster - 1 Inch Plastic Ball

1 x HDPE - Black on White - 6 inches x 12 inches x 0.25 inch

2 x Pololu Wheel 90 mm × 10 mm - Black

4 x Screw - #4-40 - 3/8 inch

1 x SparkFun Cerberus USB Cable

*/

// Include the library code:

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// NeoPixels

#include <Adafruit_NeoPixel.h>

// Solarbotics RM2 -> 1

#define MOTOR1_IN1 2

#define MOTOR1_IN2 3

// Solarbotics RM2 -> 2

#define MOTOR2_IN1 4

#define MOTOR2_IN2 5

// Power be 0-1023

int iPower = 0;

String POW = "";

// Joystick was sitting around 520 for the vertical and horizontal values

// Will be 0-1023

// Vertical

int vertical;

String VER = "";

// Horizontal

// Will be 0-1023

int horizontal;

String HOR = "";

// Select

// Will be HIGH (1) if not pressed, and LOW (0) if pressed

int select1 = 0;

String SEL = "";

int firstClosingBracket = 0;

// Map Vertical and Horizontal

int mapVer = 0;

int mapHor = 0;

int iVer = 1;

int iHor = 0;

// NeoPixels

// On digital pin 6

#define PIN 6

// NeoPixels NUMPIXELS = 1

#define NUMPIXELS 1

// Pixels

Adafruit_NeoPixel pixels = Adafruit_NeoPixel(NUMPIXELS, PIN, NEO_GRB + NEO_KHZ800);

// Red

int red = 0;

// Green

int green = 0;

// Blue

int blue = 0;

// Neopix

int iNeo = 0;

// Value

int zz = 0;

// Process Message

// Start

bool bStart = false;

// End

bool bEnd = false;

// Variable to store the incoming byte

int incb = 0;

// Message

String msg = "";

// Index

byte in = 0;

int x = 0;

// Software Version Information

String sver = "12-23r";

// Unit ID information

String uid = "";

void loop() {

// Check for serial messages

isProcessMessage();

}

getEEPROM.ino

// EEPROM

// isUID

void isUID()

{

// Is Unit ID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getNeopix.ino

// NeoPixels

// Neopix

void isNeopix()

{

// Pixels

pixels.setBrightness( 130 );

// Pixels color takes RGB values, from 0,0,0 up to 255,255,255

pixels.setPixelColor( iNeo, pixels.Color(red,green,blue) );

// This sends the updated pixel color to the hardware

pixels.show();

// Delay for a period of time (in milliseconds)

delay(50);

}

// isNUMPIXELS

void isNUMPIXELS()

{

// Neopix Value

switch ( zz ) {

case 0:

// NeoPixels Green

// Red

red = 0;

// Green

green = 255;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 1:

// NeoPixels Blue

// Red

red = 0;

// Green

green = 0;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 2:

// NeoPixels Red

// Red

red = 255;

// Green

green = 0;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 3:

// NeoPixels Yellow

// Red

red = 255;

// Green

green = 255;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 4:

// NeoPixels Magenta

// Red

red = 255;

// Green

green = 0;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 5:

// NeoPixels Cyan

// Red

red = 0;

// Green

green = 255;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 6:

// NeoPixels White

// Red

red = 255;

// Green

green = 255;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

}

}

// isNUMPIXELSoff

void isNUMPIXELSoff()

{

// Black Off

// NeoPixels

// Red

red = 0;

// Green

green = 0;

// Blue

blue = 0;

isNeopix();

}

getProcessMessage.ino

// ProcessMessage

// isProcessMessage

void isProcessMessage() {

// Loop through serial buffer one byte at a time until you reach * which will be end of message

while ( Serial.available() > 0 )

{

// Read the incoming byte:

incb = Serial.read();

// Start the message when the '<' symbol is received

if(incb == '<')

{

// Start

bStart = true;

in = 0;

msg = "";

}

// End the message when the '*' symbol is received

else if(incb == '*')

{

// End

bEnd = true;

x = msg.length();

msg.remove( x , 1);

// Done reading

break;

}

// Read the message

else

{

// Message

msg = msg + char(incb);

in++;

}

}

// Start - End

if( bStart && bEnd)

{

// isRM2Motor => Message

isRM2Motor();

// Start - End

in = 0;

msg = "";

bStart = false;

bEnd = false;

vertical;

horizontal;

iPower;

}

}

getRM2Motor.ino

// RM2 Motor

// Setup RM2 Motor

void isSetupRM2Motor() {

// Solarbotics RM2 -> 1

pinMode(MOTOR1_IN1, OUTPUT);

pinMode(MOTOR1_IN2, OUTPUT);

// Solarbotics RM2 -> 2

pinMode(MOTOR2_IN1, OUTPUT);

pinMode(MOTOR2_IN2, OUTPUT);

}

// isRM2Motor

void isRM2Motor() {

// msg = vertical + "|" + horizontal + "|" + select + "|" + iValue + "|" + sver + "|" + uid

firstClosingBracket = 0;

// Vertical

firstClosingBracket = msg.indexOf('|');

VER = msg;

VER.remove(firstClosingBracket);

vertical = VER.toInt();

// Horizontal

firstClosingBracket = firstClosingBracket + 1;

msg.remove(0, firstClosingBracket );

firstClosingBracket = msg.indexOf('|');

HOR = msg;

HOR.remove(firstClosingBracket);

horizontal = HOR.toInt();

// Select

firstClosingBracket = firstClosingBracket + 1;

msg.remove(0, firstClosingBracket );

firstClosingBracket = msg.indexOf('|');

SEL = msg;

SEL.remove(firstClosingBracket);

select1 = SEL.toInt();

// Power

firstClosingBracket = firstClosingBracket + 1;

msg.remove(0, firstClosingBracket );

firstClosingBracket = msg.indexOf('|');

POW = msg;

POW.remove(firstClosingBracket);

iPower = POW.toInt();

// Set the direction

// Joystick was sitting around 520 for the vertical and horizontal values

// Will be 0-1023

mapVer = map(vertical, 0, 1023, -512, 512);

mapHor = map(horizontal, 0, 1023, -512, 512);

// Power

iPower = map(iPower, 0, 1023, 80, 200);

// Vertical and Horizontal

if ( mapVer == -512 ) {

// Backward

// NeoPixels Blue

zz = 1;

isNUMPIXELS();

iVer = 1;

} else if ( mapVer == 512 ) {

// Forward

// NeoPixels Green

zz = 0;

isNUMPIXELS();

iVer = 2;

} else if ( mapHor == -512 ) {

// Left

// NeoPixels Yellow

zz = 3;

isNUMPIXELS();

iVer = 3;

} else if ( mapHor == 512 ) {

// Right

// NeoPixels Magenta

zz = 4;

isNUMPIXELS();

iVer = 4;

} else {

// Stop

// NeoPixels Red

zz = 2;

isNUMPIXELS();

iVer = 5;

}

// XBee Car

switch ( iVer ) {

case 1:

// Solarbotics RM2 -> 1 Forward

digitalWrite(MOTOR1_IN1, LOW);

analogWrite(MOTOR1_IN2, iPower);

delay(10);

// Solarbotics RM2 -> 2 Forward

digitalWrite(MOTOR2_IN2, LOW);

analogWrite(MOTOR2_IN1, iPower);

delay(10);

break;

case 2:

// Solarbotics RM2 -> 1 Backward

digitalWrite(MOTOR1_IN2, LOW);

analogWrite(MOTOR1_IN1, iPower);

delay(10);

// Solarbotics RM2 -> 2 Backward

digitalWrite(MOTOR2_IN1, LOW);

analogWrite(MOTOR2_IN2, iPower);

delay(10);

break;

case 3:

// Right

// Solarbotics RM2 -> 1 Forward

digitalWrite(MOTOR1_IN1, LOW);

analogWrite(MOTOR1_IN2, iPower);

delay(10);

// Solarbotics RM2 -> 2 Forward

digitalWrite(MOTOR2_IN1, LOW);

analogWrite(MOTOR2_IN2, iPower);

delay(10);

break;

case 4:

// Left

// Solarbotics RM2 -> 1 Backward

digitalWrite(MOTOR1_IN2, LOW);

analogWrite(MOTOR1_IN1, iPower);

delay(10);

// Solarbotics RM2 -> 2 Backward

digitalWrite(MOTOR2_IN2, LOW);

analogWrite(MOTOR2_IN1, iPower);

delay(10);

break;

case 5:

// Stop

// NeoPixels Red

//zz = 2;

//isNUMPIXELS();

// Solarbotics RM2 -> 1

digitalWrite(MOTOR1_IN1, LOW);

analogWrite(MOTOR1_IN2, 0);

delay(10);

// Solarbotics RM2 -> 2

digitalWrite(MOTOR2_IN1, LOW);

analogWrite(MOTOR2_IN2, 0);

delay(10);

break;

}

}

setup.ino

// Setup

void setup() {

// Open the serial port at 9600 bps:

Serial.begin( 9600 );

// Pause

delay(5);

// EEPROM Unit ID

isUID();

// Pause

delay(5);

// Setup Solarbotics RM2 Motor

isSetupRM2Motor();

// Pause

delay(5);

// NeoPixels

// This initializes the NeoPixel library

pixels.begin();

// Delay for a period of time (in milliseconds)

delay(50);

// isNUMPIXELS Off

isNUMPIXELSoff();

}

——

People can contact us: https://www.donluc.com/?page_id=1927

Technology Experience

- Single-Board Microcontrollers (PIC, Arduino, Raspberry Pi,Espressif, etc…)

- IoT

- Robotics

- Camera and Video Capture Receiver Stationary, Wheel/Tank and Underwater Vehicle

- Unmanned Vehicles Terrestrial and Marine

- Research & Development (R & D)

- Desktop Applications (Windows, OSX, Linux, Multi-OS, Multi-Tier, etc…)

- Mobile Applications (Android, iOS, Blackberry, Windows Mobile, Windows CE, etc…)

- Web Applications (LAMP, Scripting, Java, ASP, ASP.NET, RoR, Wakanda, etc…)

- Social Media Programming & Integration (Facebook, Twitter, YouTube, Pinterest, etc…)

- Content Management Systems (WordPress, Drupal, Joomla, Moodle, etc…)

- Bulletin Boards (phpBB, SMF, Vanilla, jobberBase, etc…)

- eCommerce (WooCommerce, OSCommerce, ZenCart, PayPal Shopping Cart, etc…)

Instructor and E-Mentor

- IoT

- PIC Microcontrollers

- Arduino

- Raspberry Pi

- Espressif

- Robotics

- DOS, Windows, OSX, Linux, iOS, Android, Multi-OS

- Linux-Apache-PHP-MySQL

Follow Us

J. Luc Paquin – Curriculum Vitae – 2022 English & Español

https://www.jlpconsultants.com/luc/

Web: https://www.donluc.com/

Web: https://www.jlpconsultants.com/

Facebook: https://www.facebook.com/neosteam.labs.9/

YouTube: https://www.youtube.com/channel/UC5eRjrGn1CqkkGfZy0jxEdA

Twitter: https://twitter.com/labs_steam

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Instagram: https://www.instagram.com/neosteamlabs/

Don Luc

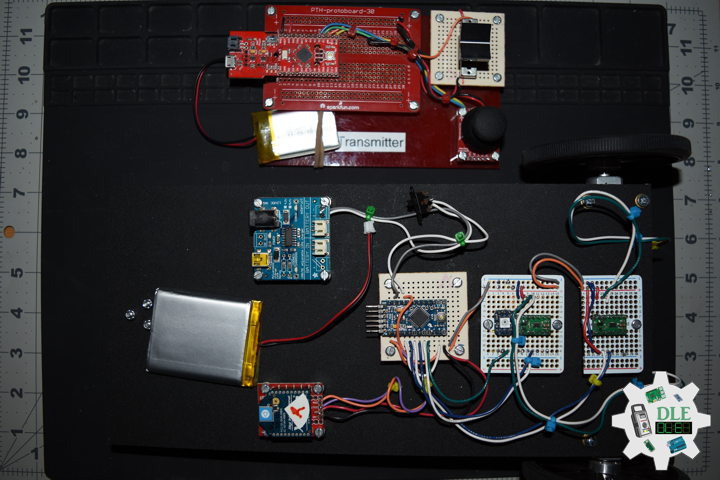

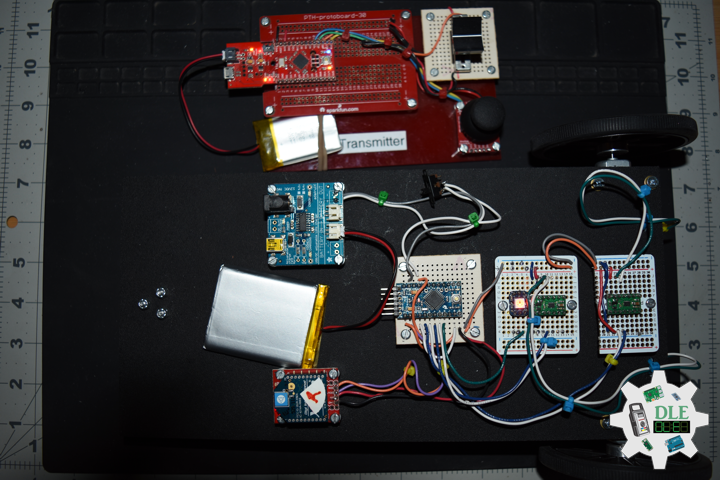

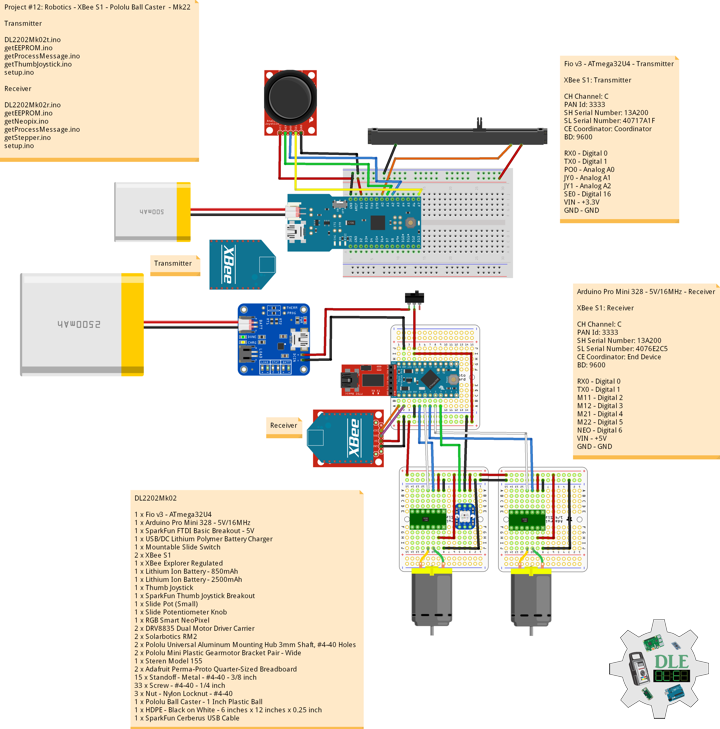

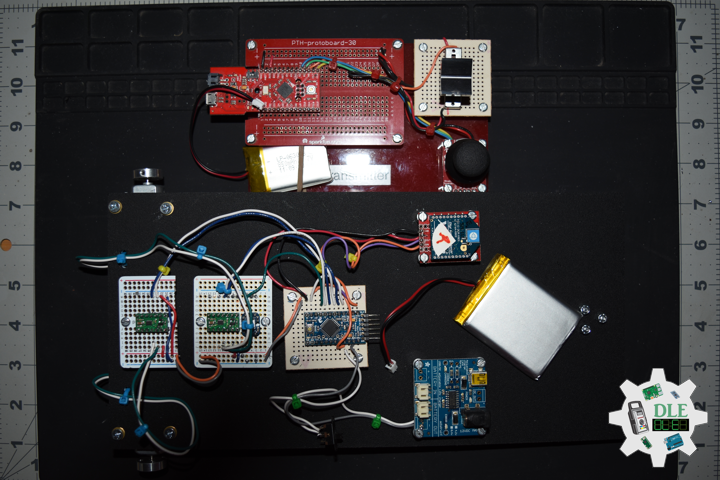

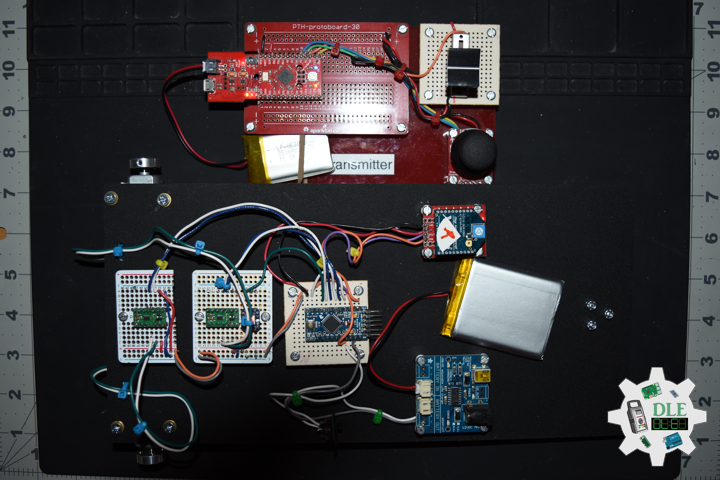

Project #12: Robotics – Pololu Ball Caster – Mk22

——

#DonLucElectronics #DonLuc #Robotics #Arduino #Fio #ArduinoProMini #XBee #DCMotor #MotorDriver #Project #Fritzing #Programming #Electronics #Microcontrollers #Consultant

——

——

——

——

Pololu Ball Caster with 1 Inch Plastic Ball and Ball Bearings

This ball caster uses a 1 inch diameter plastic ball and has an overall height of 1.1 inches (29 mm). The two-part housing snaps together to securely enclose the ball and three ball bearings that minimize friction between the ball and the ABS housing.

This ball caster kit includes a two-part black ABS housing, a 1 inch diameter POM plastic ball, three 3 mm × 7 mm × 3 mm ball bearings, and three dowel pins used to hold the ball bearings. When assembled, the ball caster is capable of rolling in any direction with low friction, making it suitable for use as a third contact point for wheeled, differential-drive robots weighing up to around ten pounds.

The base piece of the housing has holes for three mounting screws and slots for ball bearings. The second part of the housing snaps into the base piece to secure the ball and ball bearings. The assembled ball caster has an overall height of 1.1 inches (29 mm).

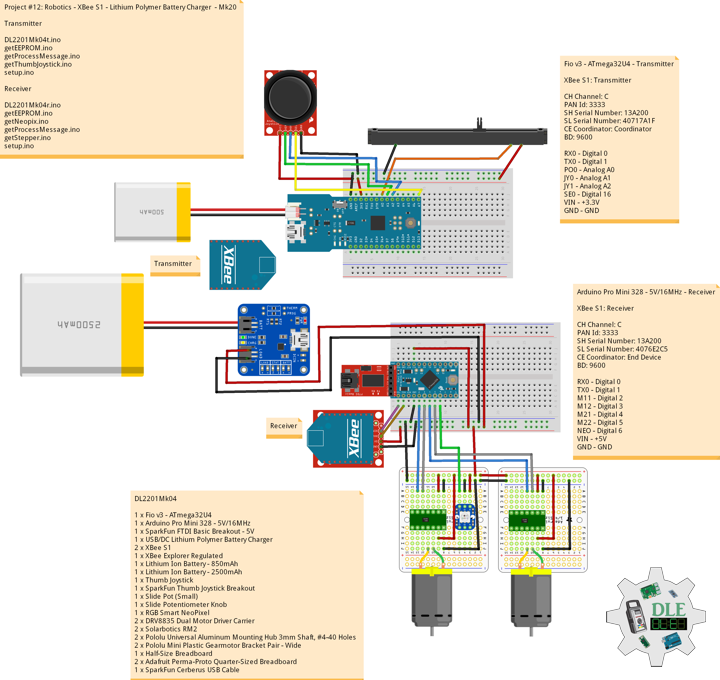

DL2202Mk02

1 x Fio v3 – ATmega32U4

1 x Arduino Pro Mini 328 – 5V/16MHz

1 x SparkFun FTDI Basic Breakout – 5V

1 x USB/DC Lithium Polymer Battery Charger

1 x Mountable Slide Switch

2 x XBee S1

1 x XBee Explorer Regulated

1 x Lithium Ion Battery – 850mAh

1 x Lithium Ion Battery – 2500mAh

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

1 x Slide Pot (Small)

1 x Slide Potentiometer Knob

1 x RGB Smart NeoPixel

2 x DRV8835 Dual Motor Driver Carrier

2 x Solarbotics RM2

2 x Pololu Universal Aluminum Mounting Hub 3mm Shaft, #4-40 Holes

2 x Pololu Mini Plastic Gearmotor Bracket Pair – Wide

1 x Steren Model 155

2 x Adafruit Perma-Proto Quarter-Sized Breadboard

15 x Standoff – Metal – #4-40 – 3/8 inch

33 x Screw – #4-40 – 1/4 inch

3 x Nut – Nylon Locknut – #4-40

1 x Pololu Ball Caster – 1 Inch Plastic Ball

1 x HDPE – Black on White – 6 inches x 12 inches x 0.25 inch

1 x SparkFun Cerberus USB Cable

Fio v3 – ATmega32U4 – Transmitter

XBee S1: Transmitter

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 40717A1F

CE Coordinator: Coordinator

BD: 9600

RX0 – Digital 0

TX0 – Digital 1

PO0 – Analog A0

JY0 – Analog A1

JY1 – Analog A2

SE0 – Digital 16

VIN – +3.3V

GND – GND

——

DL2202Mk02t.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Pololu Ball Caster - Mk22

02-02

Transmitter

DL2202Mk02t.ino

1 x Fio v3 - ATmega32U4

1 x XBee S1

1 x Lithium Ion Battery - 850mAh

1 x Thumb Joystick

1 x SparkFun Thumb Joystick Breakout

1 x Slide Pot (Small)

1 x Slide Potentiometer Knob

1 x SparkFun Cerberus USB Cable

*/

// Include the Library Code

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// Communication

unsigned long dTime = 200;

// Slide Pot (Small)

// Select the input pin for the slide pot

// Power

const int iSP1 = A0;

// Power to store the value

int iPower = 0;

// Connections to joystick

// Vertical

const int VERT = A1;

// Horizontal

const int HORIZ = A2;

// Pushbutton

const int SEL = 16;

// Initialize variables for analog and digital values

int vertical;

int horizontal;

int select;

// Software Version Information

// Version

String sver = "12-22t";

// Unit ID Information

// UID

String uid = "";

void loop()

{

// Thumb Joystick

isThumbJoystick();

// Process Message

isProcessMessage();

delay( dTime );

}

getEEPROM.ino

// EEPROM

// is UID

void isUID()

{

// Is Unit ID

// UID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getProcessMessage.ino

// Process Message

// isProcessMessage

void isProcessMessage() {

// Loop through serial buffer

// Print = "<" + vertical + "|" + horizontal + "|" + select + "|" + iValue + "|" + sver + "|" + uid + "*"

Serial1.print( '<' );

Serial1.print( vertical );

Serial1.print( '|' );

Serial1.print( horizontal );

Serial1.print( '|' );

Serial1.print( select );

Serial1.print( '|' );

Serial1.print( iPower );

Serial1.print( '|' );

Serial1.print( sver );

Serial1.print( '|' );

Serial1.print( uid );

Serial1.println( '*' );

}

getThumbJoystick.ino

// Thumb Joystick

void isThumbJoystick() {

// Read all values from the joystick

// Joystick was sitting around 520 for the vertical and horizontal values

// Will be 0-1023

vertical = analogRead(VERT);

// Will be 0-1023

horizontal = analogRead(HORIZ);

// Will be HIGH (1) if not pressed, and LOW (0) if pressed

select = digitalRead(SEL);

// Read the value

// Power be 0-1023

iPower = analogRead( iSP1 );

}

setup.ino

// Setup

void setup()

{

// EEPROM Unit ID

isUID();

// Pause

delay(5);

// Make the SEL line an input

pinMode(SEL, INPUT_PULLUP);

// Open Serial1 port at 9600 baud

Serial1.begin( 9600 );

// Pause

delay(5);

}

——

Arduino Pro Mini 328 – 5V/16MHz – Receiver

XBee S1: Receiver

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 4076E2C5

CE Coordinator: End Device

BD: 9600

RX0 – Digital 0

TX0 – Digital 1

M11 – Digital 2

M12 – Digital 3

M21 – Digital 4

M22 – Digital 5

NEO – Digital 6

VIN – +5V

GND – GND

DL2202Mk02r.ino

/* ***** Don Luc Electronics © *****

Software Version Information

Project #12: Robotics - Pololu Ball Caster - Mk22

02-02

Receiver

DL2202Mk02r.ino

1 x Arduino Pro Mini 328 - 5V/16MHz

1 x SparkFun FTDI Basic Breakout - 5V

1 x XBee S1

1 x XBee Explorer Regulated

1 x USB/DC Lithium Polymer Battery Charger

1 x Mountable Slide Switch

1 x Lithium Ion Battery - 2500mAh

1 x RGB Smart NeoPixel

2 x DRV8835 Dual Motor Driver Carrier

2 x Solarbotics RM2

2 x Pololu Universal Aluminum Mounting Hub 3mm Shaft, #4-40 Holes

2 x Pololu Mini Plastic Gearmotor Bracket Pair - Wide

1 x Steren Model 155

2 x Adafruit Perma-Proto Quarter-Sized Breadboard

15 x Standoff - Metal - #4-40 - 3/8 inch

33 x Screw - #4-40 - 1/4 inch

3 x Nut - Nylon Locknut - #4-40

1 x Pololu Ball Caster - 1 Inch Plastic Ball

1 x HDPE - Black on White - 6 inches x 12 inches x 0.25 inch

1 x SparkFun Cerberus USB Cable

*/

// Include the library code:

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// NeoPixels

#include <Adafruit_NeoPixel.h>

// Solarbotics RM2 -> 1

#define MOTOR1_IN1 2

#define MOTOR1_IN2 3

// Solarbotics RM2 -> 2

#define MOTOR2_IN1 4

#define MOTOR2_IN2 5

// Power be 0-1023

int iPower = 0;

String POW = "";

// Joystick was sitting around 520 for the vertical and horizontal values

// Will be 0-1023

// Vertical

int vertical;

String VER = "";

// Horizontal

// Will be 0-1023

int horizontal;

String HOR = "";

// Select

// Will be HIGH (1) if not pressed, and LOW (0) if pressed

int select1 = 0;

String SEL = "";

int firstClosingBracket = 0;

// Map Vertical and Horizontal

int mapVer = 0;

int mapHor = 0;

int iVer = 1;

int iHor = 0;

// NeoPixels

// On digital pin 6

#define PIN 6

// NeoPixels NUMPIXELS = 1

#define NUMPIXELS 1

// Pixels

Adafruit_NeoPixel pixels = Adafruit_NeoPixel(NUMPIXELS, PIN, NEO_GRB + NEO_KHZ800);

// Red

int red = 0;

// Green

int green = 0;

// Blue

int blue = 0;

// Neopix

int iNeo = 0;

// Value

int zz = 0;

// Process Message

// Start

bool bStart = false;

// End

bool bEnd = false;

// Variable to store the incoming byte

int incb = 0;

// Message

String msg = "";

// Index

byte in = 0;

int x = 0;

// Software Version Information

String sver = "12-22r";

// Unit ID information

String uid = "";

void loop() {

// Check for serial messages

isProcessMessage();

}

getEEPROM.ino

// EEPROM

// isUID

void isUID()

{

// Is Unit ID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getNeopix.ino

// NeoPixels

// Neopix

void isNeopix()

{

// Pixels

pixels.setBrightness( 130 );

// Pixels color takes RGB values, from 0,0,0 up to 255,255,255

pixels.setPixelColor( iNeo, pixels.Color(red,green,blue) );

// This sends the updated pixel color to the hardware

pixels.show();

// Delay for a period of time (in milliseconds)

delay(50);

}

// isNUMPIXELS

void isNUMPIXELS()

{

// Neopix Value

switch ( zz ) {

case 0:

// NeoPixels Green

// Red

red = 0;

// Green

green = 255;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 1:

// NeoPixels Blue

// Red

red = 0;

// Green

green = 0;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 2:

// NeoPixels Red

// Red

red = 255;

// Green

green = 0;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 3:

// NeoPixels Yellow

// Red

red = 255;

// Green

green = 255;

// Blue

blue = 0;

// Neopix

iNeo = 0;

isNeopix();

break;

case 4:

// NeoPixels Magenta

// Red

red = 255;

// Green

green = 0;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 5:

// NeoPixels Cyan

// Red

red = 0;

// Green

green = 255;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

case 6:

// NeoPixels White

// Red

red = 255;

// Green

green = 255;

// Blue

blue = 255;

// Neopix

iNeo = 0;

isNeopix();

break;

}

}

// isNUMPIXELSoff

void isNUMPIXELSoff()

{

// Black Off

// NeoPixels

// Red

red = 0;

// Green

green = 0;

// Blue

blue = 0;

isNeopix();

}

getProcessMessage.ino

// ProcessMessage

// isProcessMessage